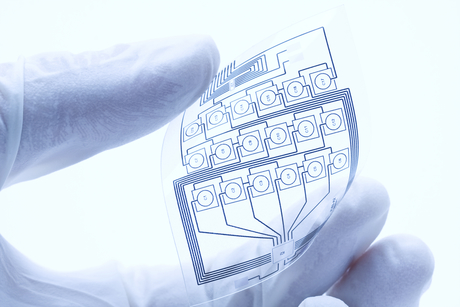

The future is flexible

A European Union-funded project that has created flexible lighting foils produced in a roll-to-roll method holds potential for the large-scale production of low-cost LED lighting panels and solar cells.

The TREASORES project received just over €9 million in funding and aimed to find innovative solutions and develop new technologies to reduce the manufacturing costs of LED lighting, solar cells and other organic electronic devices. Its most important contribution has been the development and scaling-up of manufacturing processes for new barrier materials and transparent electrodes used in advanced flexible optoelectronics.

Transparent electrodes to reduce cost and improve efficiency

It is anticipated that three electrodes on flexible substrates (using thin silver, metal fibres or carbon nanotubes) will start commercial production this year. Tests were carried out with different types of optoelectronic devices, using rolls measuring 100 metres in length.

The use of such roll-to-roll (R2R) processing is comparable to the methods used for newspaper printing and the new electrodes produced have demonstrated suitability for complex solar cells and light sources.

These innovative processing methods hold the potential to make solar cells and light sources less expensive. This would bring benefits to consumers, but would also facilitate the growth of more environmentally friendly lighting solutions, contributing to the EU’s ambitious climate change objectives.

The electrodes developed by the project are technically equivalent to those currently used by the lighting industry, which are made from indium tin oxide. However, the new electrodes are cheaper to produce and do not depend on the use of indium. Efficacy is not compromised as the new electrodes are able support a stable light source over a wide area and attain an efficiency of 25 lumens/W.

The project consortium also devised new techniques to ensure that the electrodes are able to operate even when they are bent repeatedly — a test that has the potential to be come an industry standard.

New and novel transparent barrier foils

The project also had another outcome — successful testing, development and scale-up of new manufacturing methods to create transparent barrier foils. Low-cost and high-performance barriers were created and are now being further advanced and commercially developed by Swiss-based consortium partner Flexibles Kreuzlingen.

These types of barriers are required to maximise the lifetime and efficiency of the device, a crucial element when ensuring the economic and environmental viability of solar cells.

By integrating the production of electrodes and barriers (rather than using two separate plastic substrates), the project has demonstrated that manufacturing costs can be significantly reduced, as well as allowing for thinner and more flexible device designs.

Challenges and next steps

Yet, there are challenges in producing flat, clean and smooth electrode and barrier foils; optoelectronic devices feature active layers that measure several hundred nanometres, which means that even miniscule dust particles or slight surface irregularities can affect the device yield, or could result in a shorter lifetime and inconsistent, less effective illumination.

The research formally wrapped up in October 2015, but the project partners have been continuing to address challenges, preparing patents for the technology and moving towards full commercialisation.

Why do a fifth of solar panels degrade rapidly?

An Australian study has explored a critical problem for solar energy: the phenomenon of a...

Tackling energy insecurity in remote communities

Researchers from Flinders and Macquarie Universities have presented the benefits of community-led...

Paper-thin LEDs that are kinder to the eye

A new, experimental LED is nearly as thin as paper and emits a warm, sun-like glow.