Canola plant switches to bioenergy

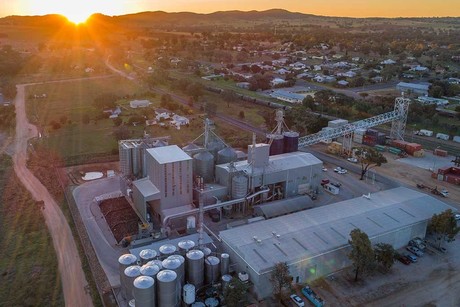

MSM Milling, an Australian oilseed crushing, refining and packaging company, is switching to bioenergy.

The project, totalling $5.38 million, involves installing a 4.88 MW biomass-fired boiler at the facility based in Manildra, regional NSW, which will be fuelled by locally sourced renewable wood chips — such as forestry thinnings, offcuts and sawmill by-products — to generate steam necessary for the canola processing operation.

The Australian Renewable Energy Agency (ARENA) is providing $2 million in funding to MSM Milling to help switch its LPG gas-fired boilers to a biomass-fuelled boiler. The project is touted to be one of Australia’s first demonstrations of a large-scale food manufacturing company seeking to reduce energy costs and environmental impact by using biomass for thermal energy. The switch to bioenergy not only replaces the use of gas in the oilseed business, it involves using sustainably sourced wood chips in a move that increases economic return to the forestry industry.

ARENA CEO Ivor Frischknecht said the funding helps to grow the currently underdeveloped biomass industry in Australia. “Bioenergy currently makes up only around 0.9% of Australia’s energy mix; however, the use of wood chips to displace gas is becoming attractive as consumers are increasingly demanding better environmental performance across product supply chains,” he said.

MSM Milling Director Bob Mac Smith said, “MSM Milling has spent a number of years researching to identify the optimal thermal energy solution for the plant to further secure our future and allow us to continue to provide sought-after trusted oil and value-added oilseed products to local and international markets. The project will significantly reduce greenhouses emissions, fossil fuel energy use and depletion, while increasing renewable energy generation in NSW — all in line with our company’s commitment to operate with the lowest carbon footprint, the highest energy and water efficiency and the least overall environmental impact.

“We’ve partnered with experienced technology providers Justsen, Uniquip Engineering and carbon energy expert Ndevr Environmental for this project and will document and share the process of technology adoption to encourage further uptake within the Australian manufacturing sector,” Mac Smith said.

Exploring grid security in a high-renewables era

Australian researchers have identified critical technical, regulatory and economic issues that...

Hallett battery project launched in SA

Owned and developed by EnergyAustralia, the Hallett BESS will be built alongside the existing...

Echandia to supply battery system for Singaporean tugboat

The agreement with the Swedish company is part of an ambitious plan to electrify Singapore's...