LAPP Australia launches harnessing solutions facility

LAPP, a global provider of branded cable and connector systems, is introducing a dedicated Harnessing Solutions Division to Australia that aims to help industries to achieve automation and digitalisation more efficiently, with OEM standards of quality control, safety and traceability.

LAPP Australia Managing Director Simon Pullinger said the new LAPP Harnessing Solutions business — with its own dedicated technology team — is the next logical step in the expansion of LAPP Australia as a driver of the country’s digital transformation.

According to the company, demand for the new service is coming from a wide range of increasingly automated and digital businesses, such as energy, automotive, water, construction, food and beverage processing, manufacturing, and mining, among others.

Pullinger said the new facility is optimally equipped to deliver harness solutions engineered for local conditions, while drawing on the strength of its LAPP Group parent, which operates in more than 100 countries. The facility’s capabilities include custom cable assemblies and wiring harnesses; prototyping and design support; production and manufacturing; testing and quality assurance; and support and repair services.

LAPP said the new business offers quality assurance and quality control procedures (QA/QC), with accreditation to best industry standards. Its technicians are dedicated harnessing specialists and qualified engineers, and work is traceable through meticulous recording of all tasks undertaken.

The range of equipment installed in the new facility includes cable feeder technology, a labeller for clear function identification, and heat shrink technology for process protection. Cable stripping, cutting and stacking is combined in one line to minimise repeat handling and maximise accuracy.

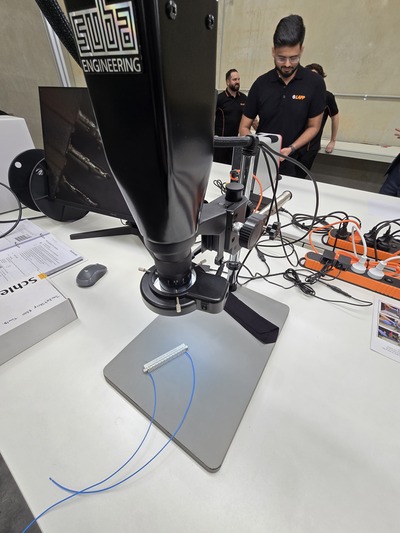

Production is further streamlined by complementary equipment including automatic Epic insert pin puncher, automatic ferrule crimper, single-cable multi-core sheath stripping machinery, single-cable/single-core sheath stripping machine, and custom-designed over-moulding and soldering machinery. Additionally, there’s benchtop connection testing equipment for a variety of connectors and cables, complementary over-braiding services, a curing oven for custom curly cables, and desktop microscopic examination for QA and production assurance and service.

Pullinger said demand for integrated harnessing solutions is coming particularly from high-demand, time-poor and market-responsive companies for which delay and downtime cost money.

“Such companies have found their digitalisation processes can quickly come under time pressure if they rely on manual and piecemeal cabling processes. Under pressure, mistakes can happen, downtime is a risk, plus the added value is zero,” he explained.

“So more and more companies are removing such issues by placing the assembly of cables, cable harnesses and drag chains in the hands of a specialist solutions provider working to top OEM standards.”

The company added that, building on the overall success of LAPP Australia, the establishment of the Harnessing Solutions business was a logical next step up the supply chain in the interests of customers seeking wider service from the one source.

Energy regulator gives verdict on Project Marinus

Tasmania and Victoria's planned energy and communications upgrade has taken another step...

SA Power Networks combats insulator pollution

The South Australian utility has established a multidisciplinary taskforce to tackle what has...

Keeping Australia's power systems stable: AEMO report

The 2025 Transition Plan for System Security explains how the nation can meet its system security...